Welcome to Anping County BT Wire Mesh Products Co., Ltd.

News

Products Catalog

News

Features of operation and maintenance of wedge wire screen baskets

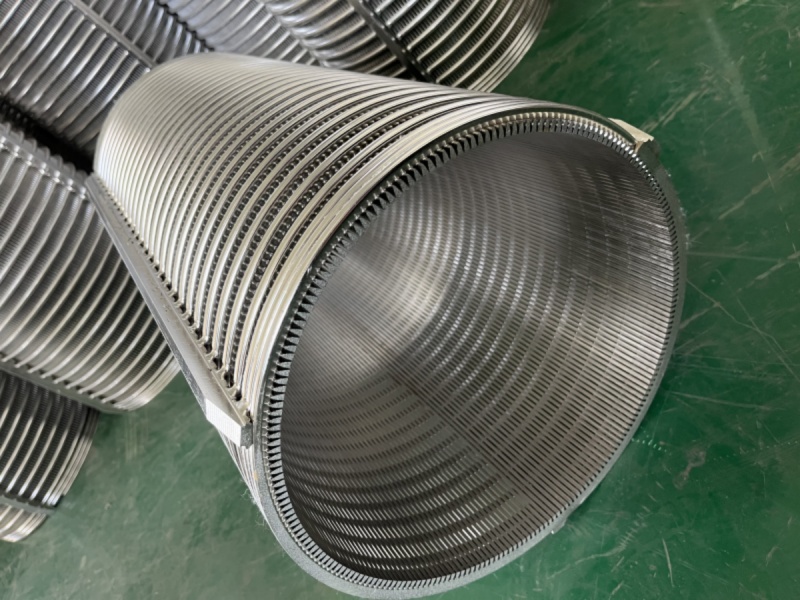

Wedge wire screen baskets for separators play an important role in the separation and filtration of materials in various industrial processes: from the separation of manure in the agricultural industry to the processing of waste in the food industry. Screens allow you to separate the solid part from the wet, ensuring the efficient operation of the separator.

In order for the separation process to be effective, it is necessary to remember that slotted screens require a careful approach to ensure their long service life and reliable operation.

The first step for successful operation is to choose the right sieve. The sieves are available in different mesh sizes and shapes, and the selection depends on the characteristics of the material that needs to be separated or filtered. It is very important to consider the particle size, material flow rate, material density and other process parameters.

The correct installation of the screen in the separator plays a decisive role in its efficient and correct operation. The slotted screen must be carefully fixed to avoid vibration and movement during operation. Correct installation also helps to prevent damage and wear. After selecting a suitable slotted screen with the optimal unit size and correctly installed, it is necessary to monitor the operation of the separator and its parameters, such as vibration speed and screen throughput. This can seriously affect the productivity and efficiency of the process. The optimization of these parameters helps to ensure high quality and long-term separation of materials.

Regular cleaning of the screens from accumulated, stuck material and contaminants is essential to maintain proper operation.

Screen Maintenance

Slotted screens, like any other element in the overall proper operation of a separator, require maintenance.

First, the screens need to be visually inspected regularly for wear, deformation and damage. This allows problems to be detected at an early stage and more serious damage to be prevented.

Second, the screens need to be systematically cleaned of material that could clog the cells to maintain their performance. Depending on what is being processed, the separator may need to be stopped regularly for cleaning.

Third, do not forget to comply with safety standards. Use the necessary protective equipment (gloves and glasses) when servicing and cleaning the screens.

Wedge wire screen baskets play an important role in various industries such as agriculture, mining, food processing, etc. Proper operation and maintenance of the screens helps ensure process efficiency and long equipment life. This also helps reduce screen repair and replacement costs, which is an important aspect of sustainable production.

Next: DSM Screen

Previous: Wedge Wire Curved Screens – High-Efficiency Filtration Solutions