Welcome to Anping County BT Wire Mesh Products Co., Ltd.

Mining Screen

Mining Screen

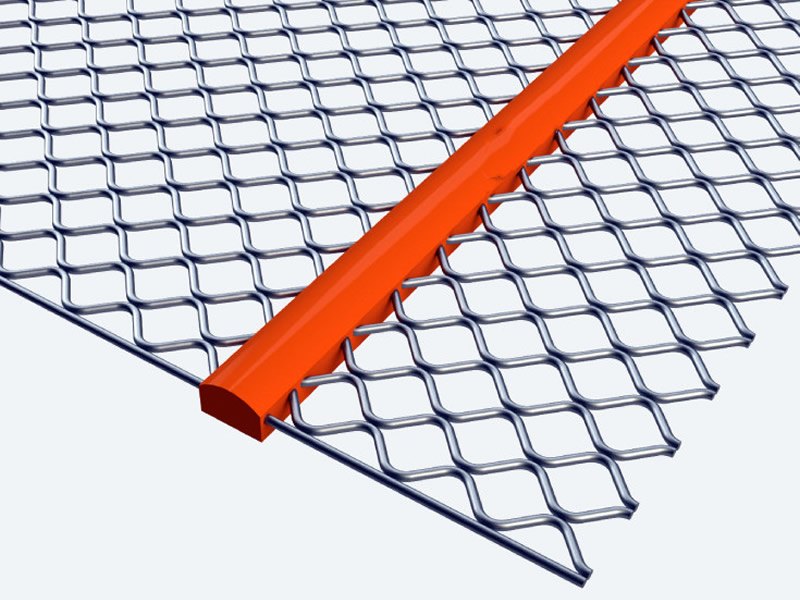

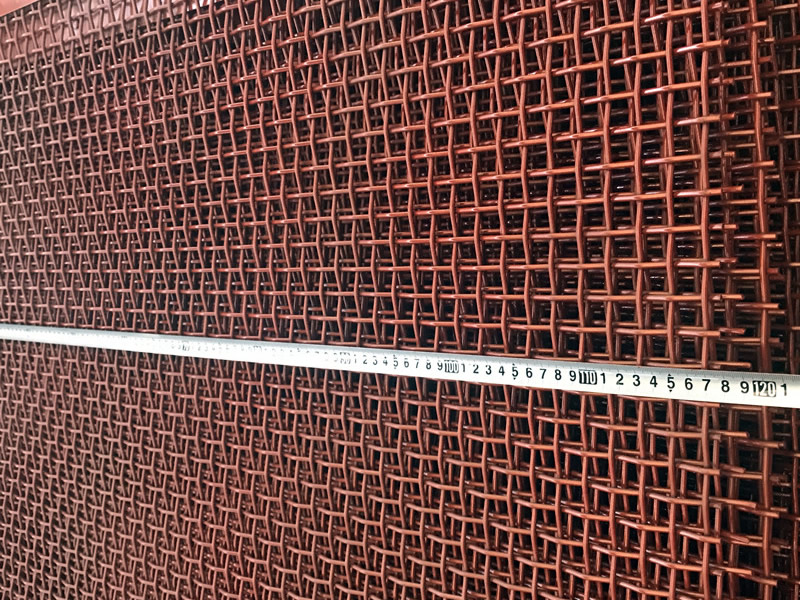

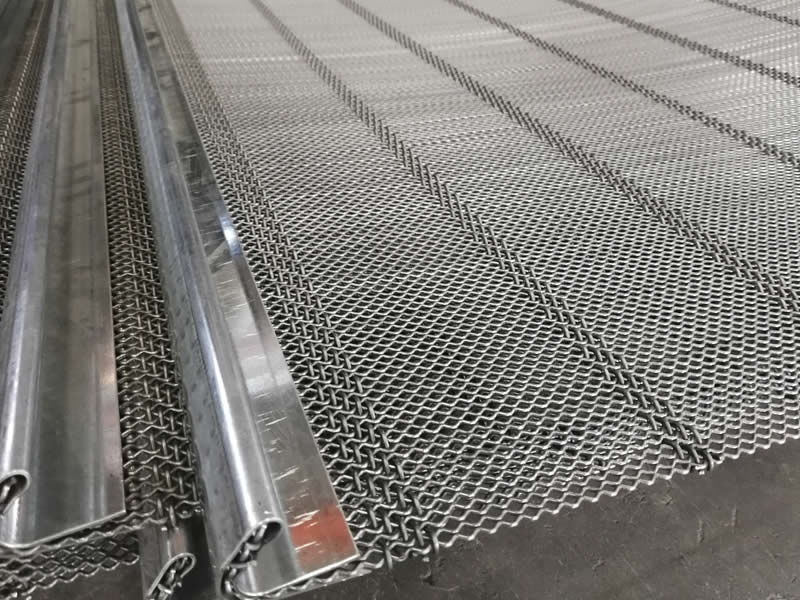

Screens are commonly utilized in mining operations and aggregates production to separate rocks, ores, and other materials by size, shape or other characteristics. Whatever your process requirements, Baitong Mesh Screen has the screening solution to fit your needs. Our screening professionals are eager to help you in finding the most productive and cost-effective solution for your application.

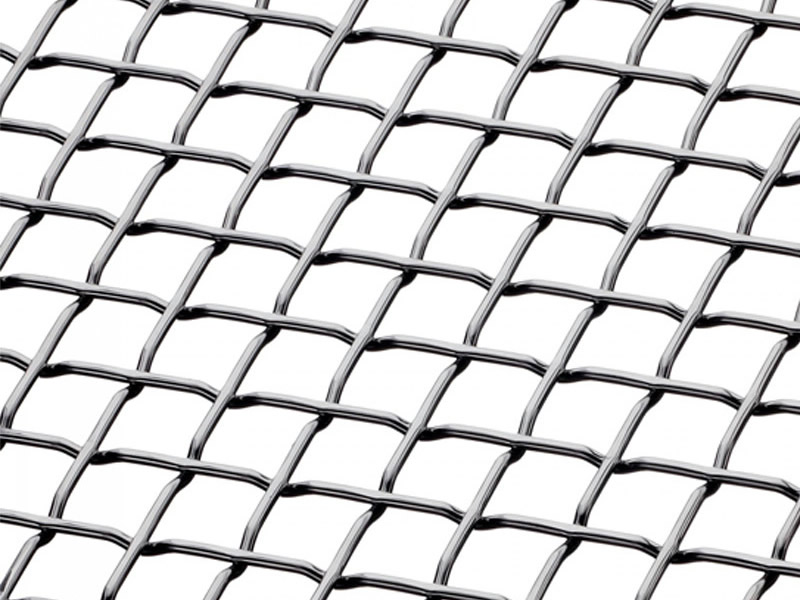

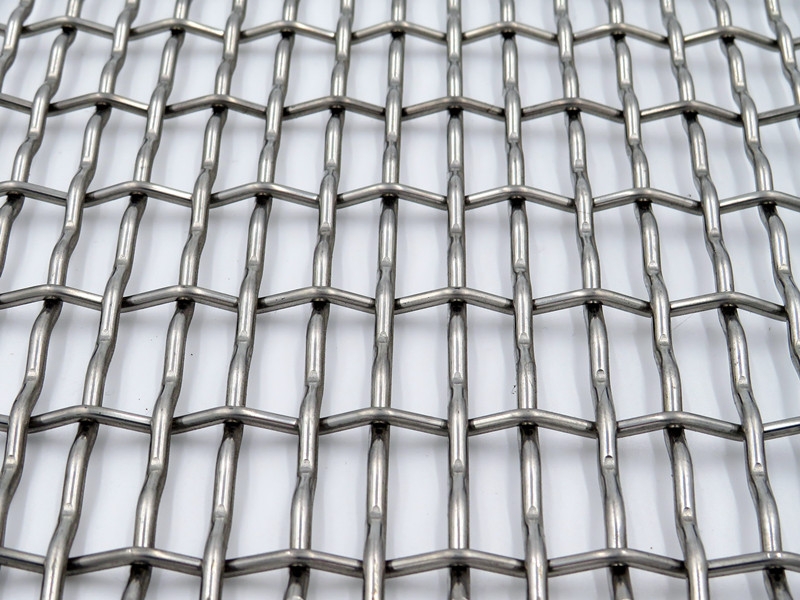

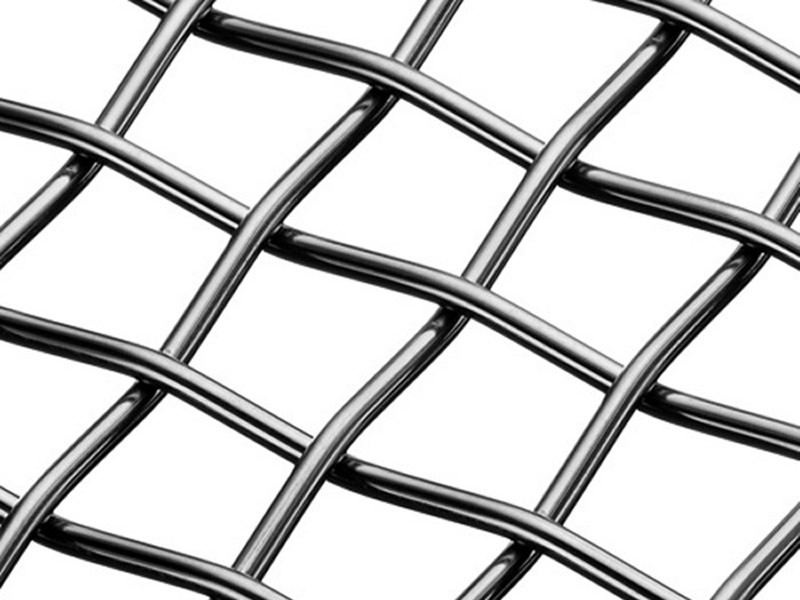

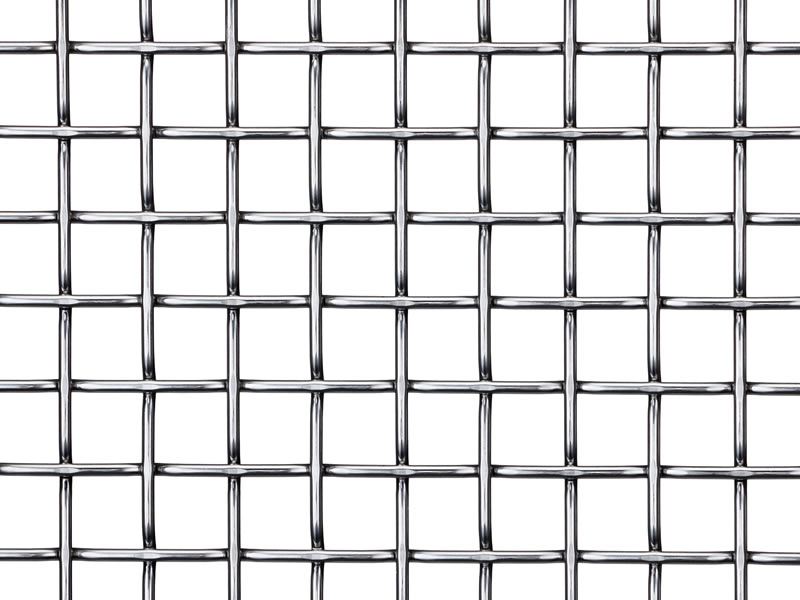

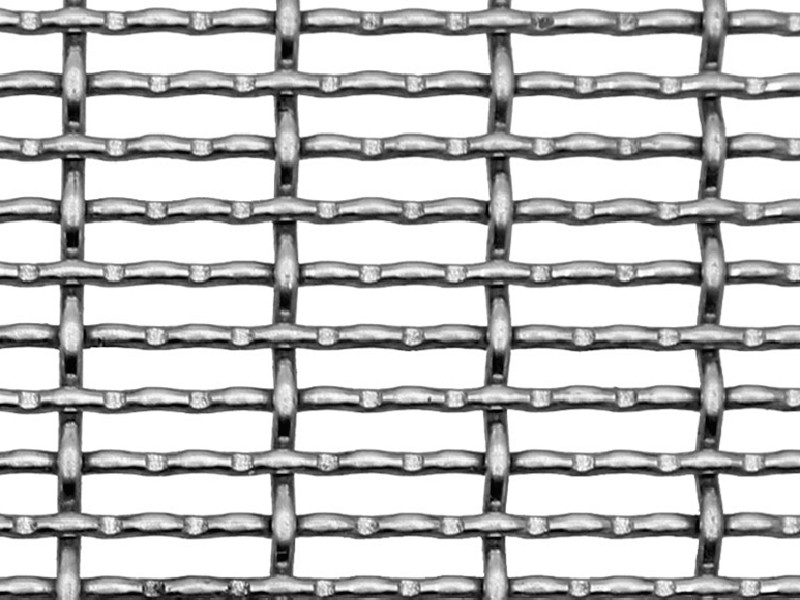

This is the most common type of woven wire mesh. It is used where the opening is relatively small in comparison to the wire diameter.

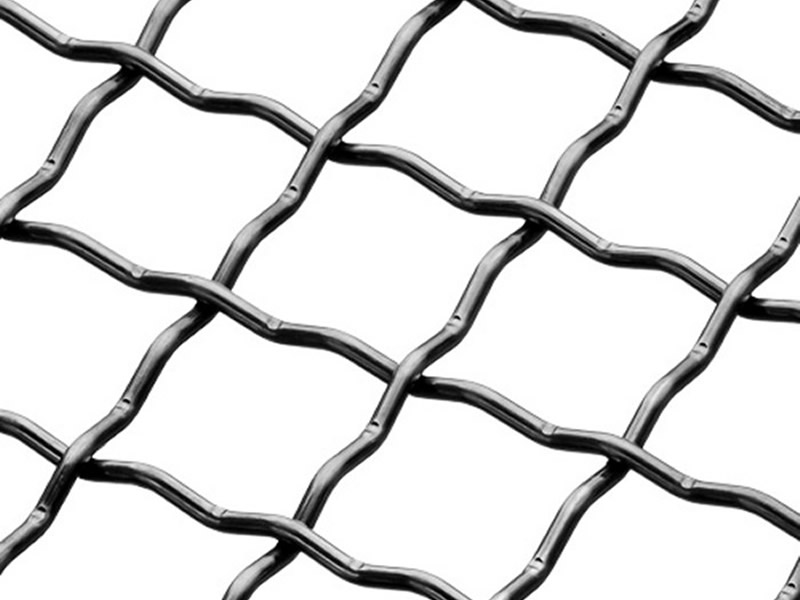

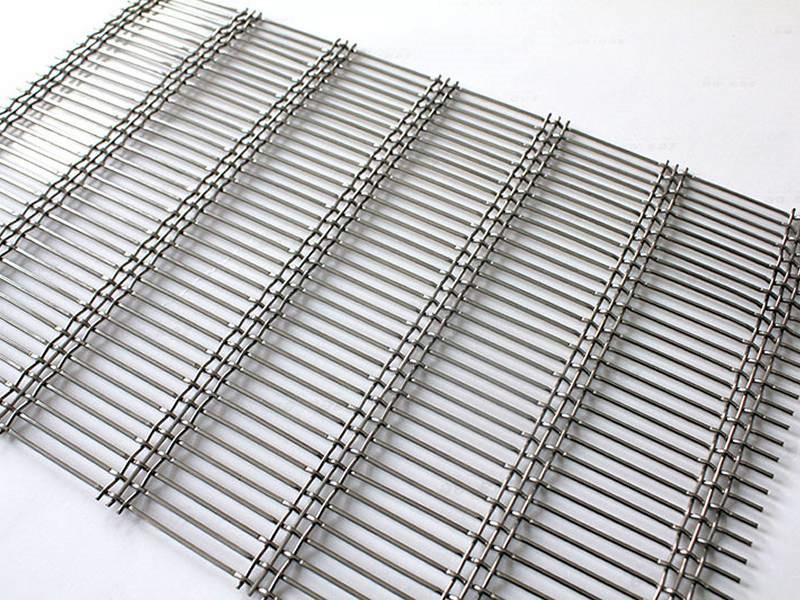

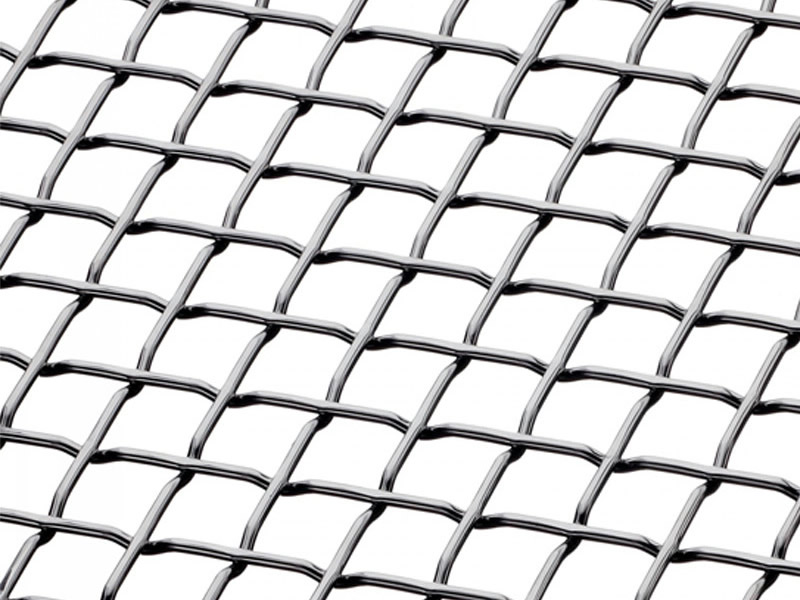

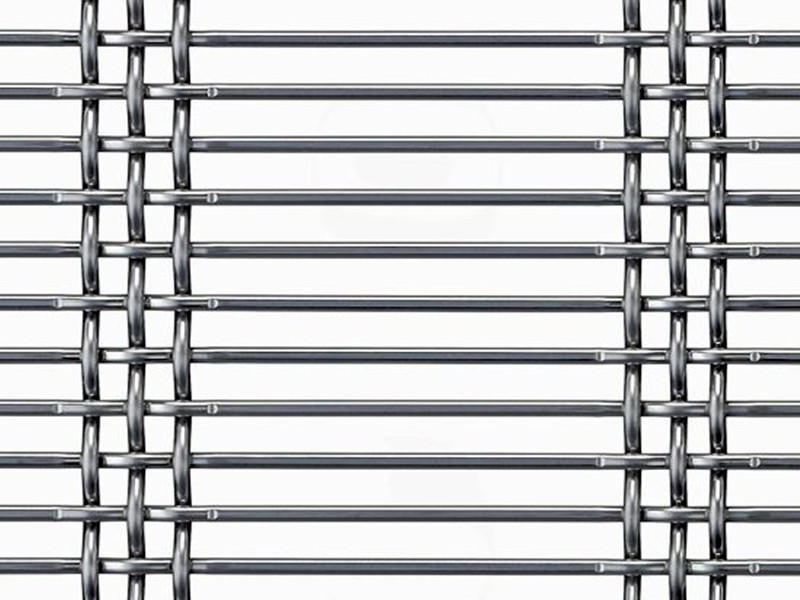

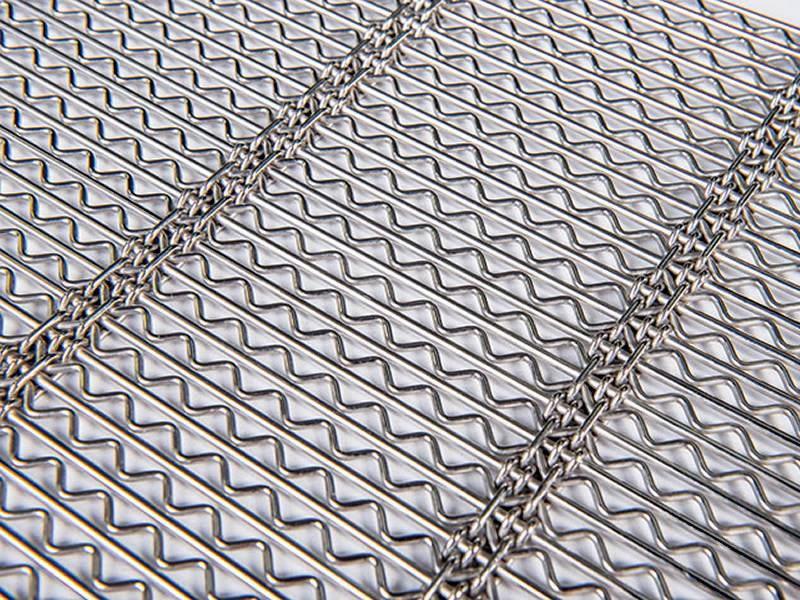

This woven wire type is used only in coarse specifications to maintain the accuracy of weave throughout screen life, where the opening is large with respect to wire diameter.

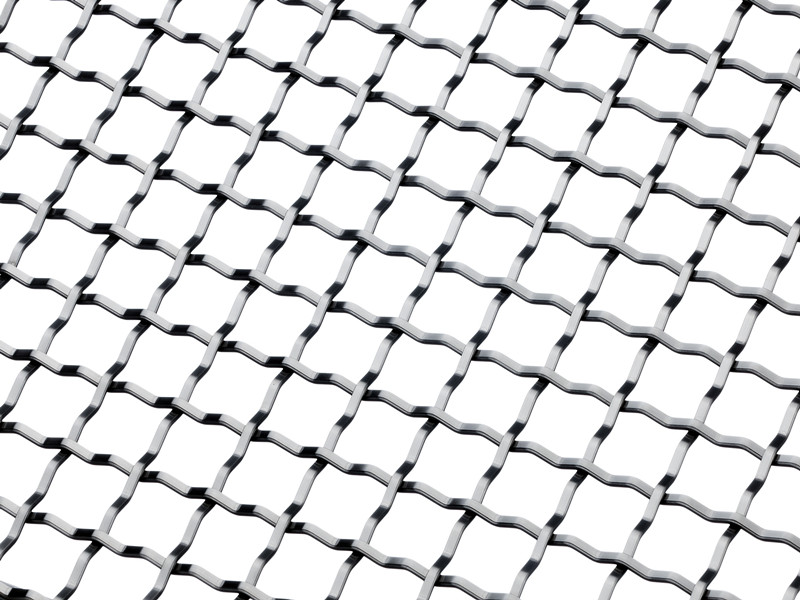

Usually start at 5/8” opening or larger. This type of wire provides long abrasive resistant life since there are no projections on top to wear. Flat top woven wire offers the least resistance to flow and is very popular in certain architectural and structural applications where a smooth surface on one side is desirable.

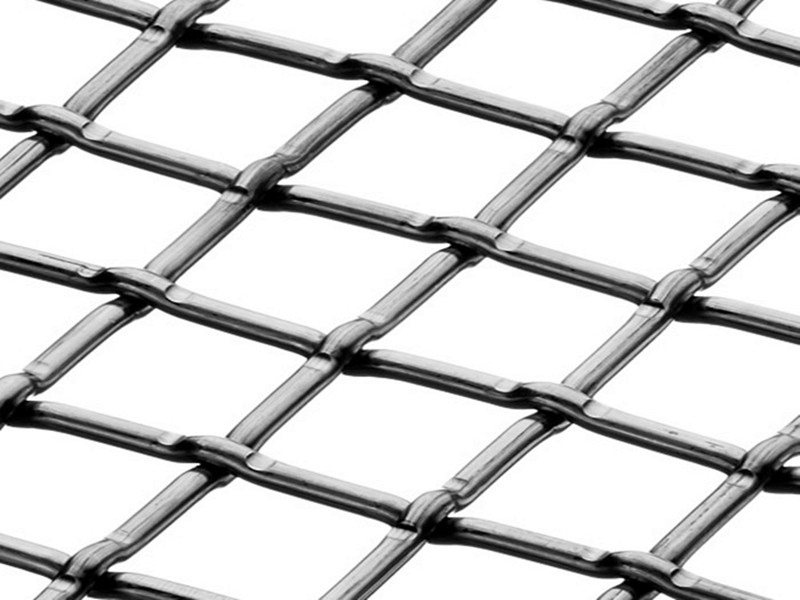

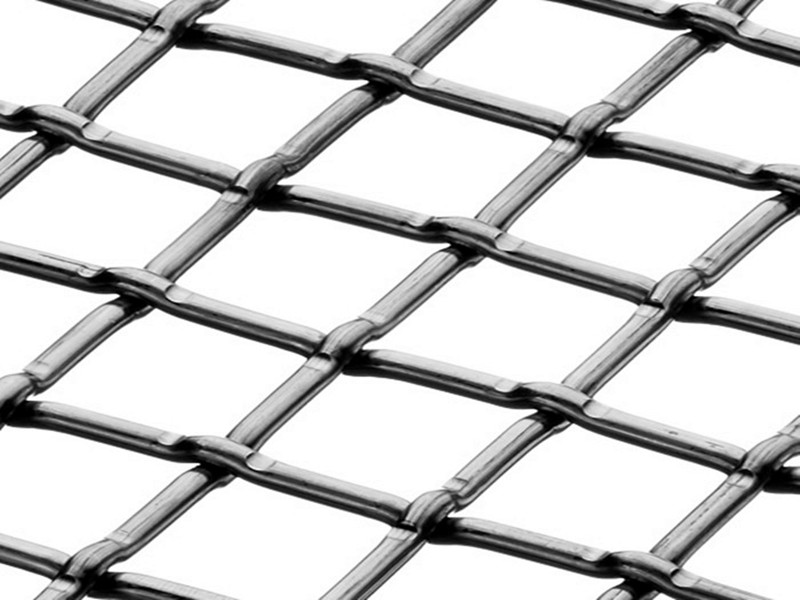

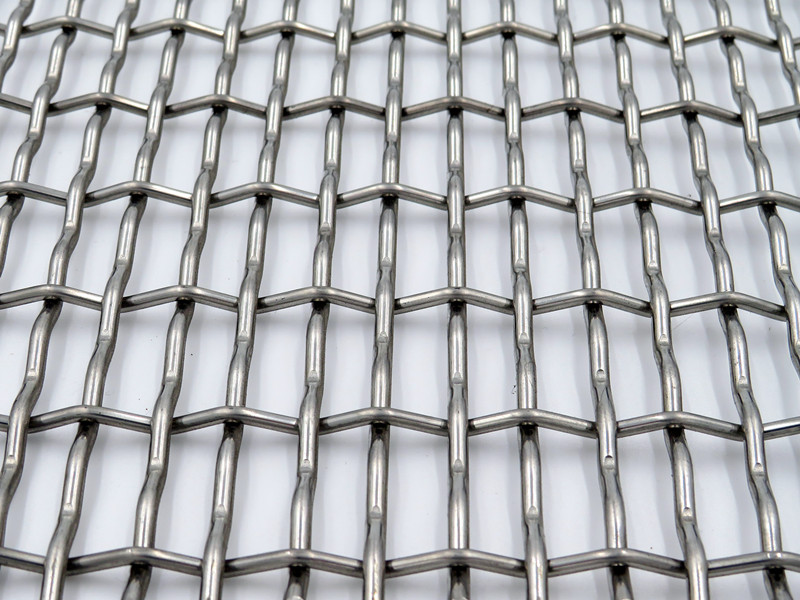

This type of wire is used in coarse weaves of lighter gauge woven wire to provide greater stability, tightness of weave and maximum rigidity. It is very common in wire mesh openings larger than 1/2”

Single-shute oblong opening solves minor blinding problems for better flow.

Long openings help keep sticky or wet material flowing freely. The Tri-Lock weave holds wires securely yet permits slight vibration to keep openings clear.

Features:

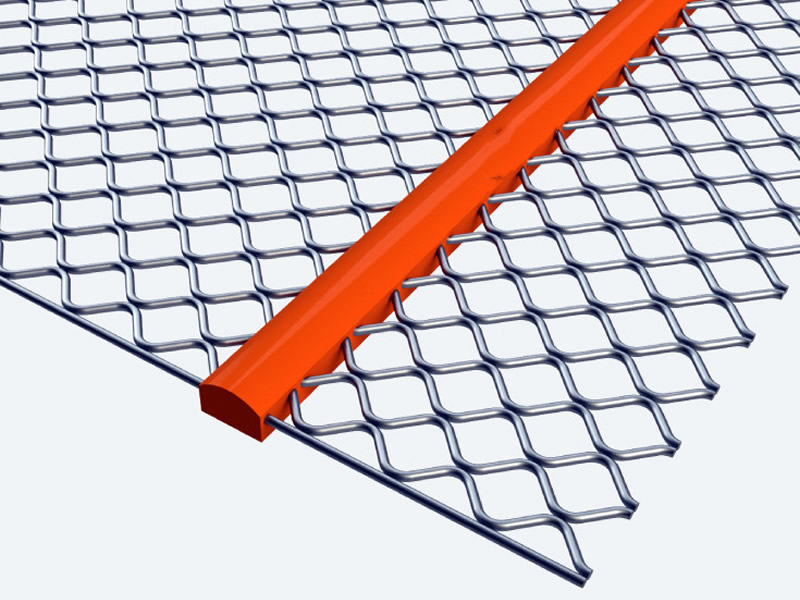

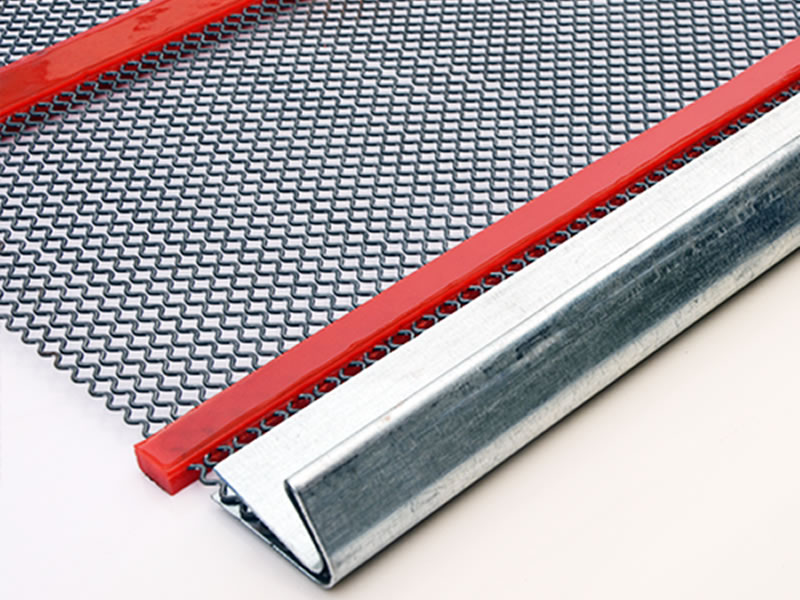

• Double strand construction both ways or with single/double combined

• Special lock-crimp / flat-top design tooling for maximum tightness and uniformity

• Wire range is 1.25mm to 5.0mm

• Suggested opening range is 1-1/4” to 5”

• Available in High Carbon, Tufflex and Type 304 Stainless Steel

• Double wire construction ensures superior tensile strengths and durability for your heavy impact, top deck screening applications.

• Guaranteed to outperform single shute wire in a comparable wire size.

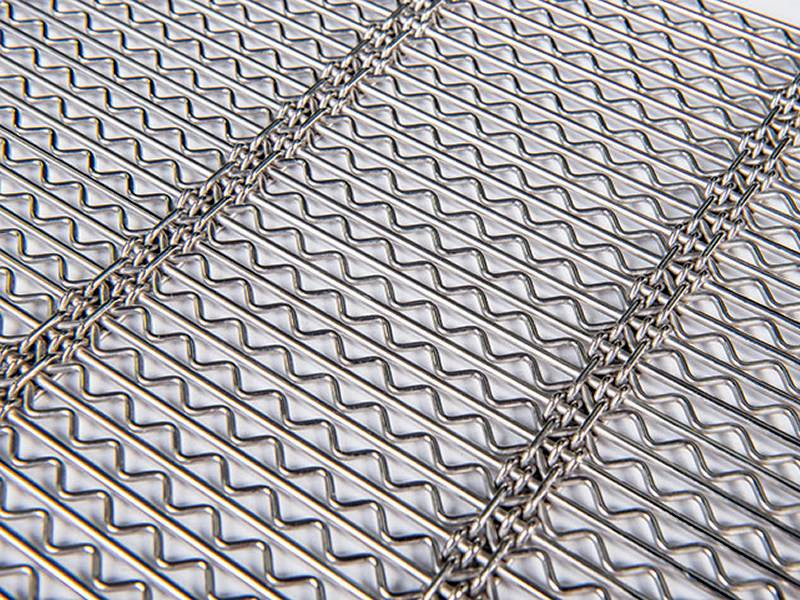

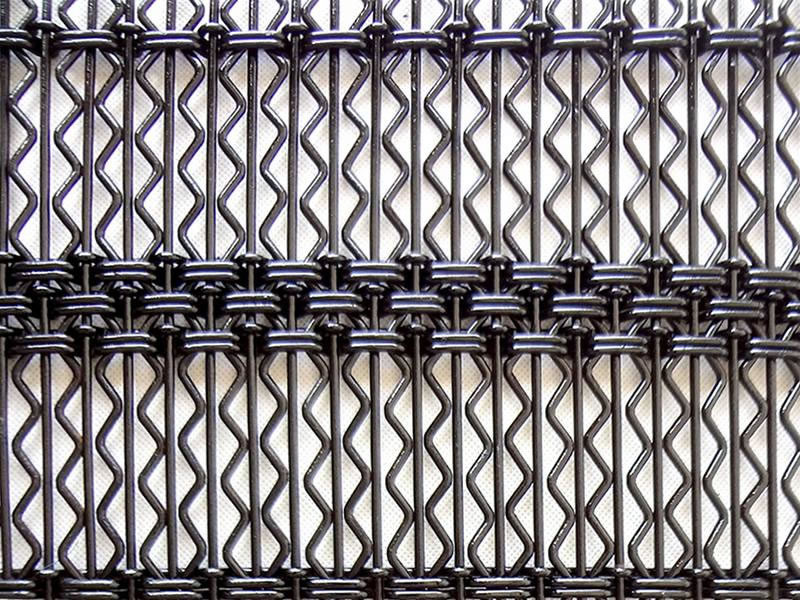

W-Style Screens

• Alternating straight and formed wires vibrate at different frequencies to clean the screening surface

• Triangular-shaped openings for accurate sizing

• More resilient to damage from oversized material

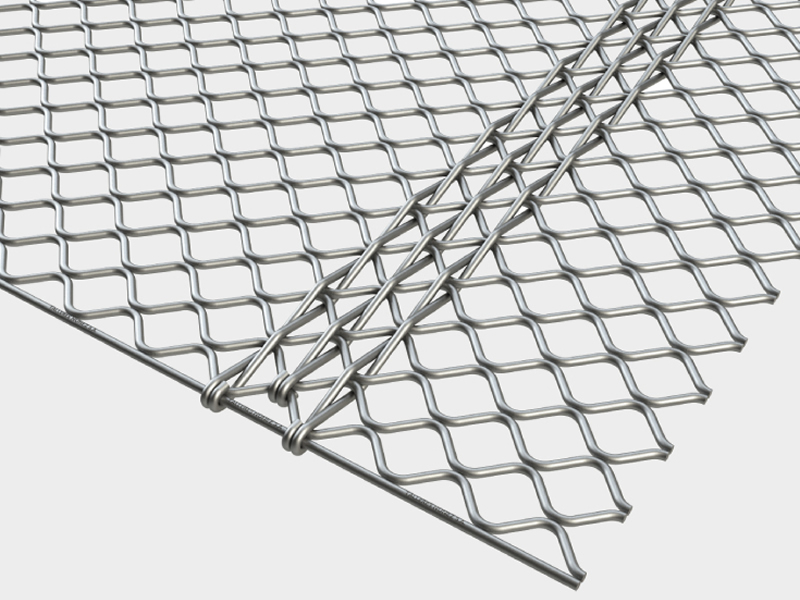

• Diamond-shaped openings for accurate sizing

• Accurately sizes dry or damp material

• Most accurate Clean Screen for sizing applications

Opening / Aperture | Wire Diameter | Open Area | Approx. Weight | ||

mm | Inch | mm | Inch | ||

25.4 | 1 | 5.72 | 0.225 | 66.62 | 13.3 |

28.58 | 1-1/8 | 5.72 | 0.225 | 69.43 | 12.2 |

31.75 | 1-1/4 | 5.72 | 0.225 | 71.8 | 10.9 |

19.05 | 3/4 | 6.17 | 0.243 | 57.06 | 19.1 |

20 |

| 6.17 | 0.243 | 58.41 | 18.6 |

22.23 | 7/8 | 6.17 | 0.243 | 61.27 | 17.3 |

25.4 | 1 | 6.17 | 0.243 | 64.73 | 15.4 |

26.99 | 1-1/16 | 6.17 | 0.243 | 66.25 | 14.6 |

28.58 | 1-1/8 | 6.17 | 0.243 | 67.64 | 13.8 |

31.75 | 1-1/4 | 6.17 | 0.243 | 70.11 | 12.6 |

25.4 | 1 | 7.19 | 0.283 | 60.74 | 19.8 |

28.58 | 1-1/8 | 7.19 | 0.283 | 63.84 | 18.2 |

31.75 | 1-1/4 | 7.19 | 0.283 | 66.48 | 16.7 |

38.1 | 1-1/2 | 7.19 | 0.283 | 70.77 | 14.5 |

25.4 | 1 | 7.92 | 0.312 | 58.11 | 24 |

28.58 | 1-1/8 | 7.92 | 0.312 | 61.31 | 22 |

31.75 | 1-1/4 | 7.92 | 0.312 | 64.06 | 20.25 |

38.1 | 1-1/2 | 7.92 | 0.312 | 68.54 | 17.5 |

41.28 | 1-5/8 | 7.92 | 0.312 | 70.40 | 16 |

44.45 | 1-3/4 | 7.92 | 0.312 | 72.04 | 15 |

50.8 | 2 | 7.92 | 0.312 | 74.84 | 13.5 |

25.4 | 1 | 9.19 | 0.362 | 53.92 | 30.9 |

31.75 | 1-1/4 | 9.19 | 0.362 | 60.14 | 26 |

38.1 | 1-1/2 | 9.19 | 0.362 | 64.91 | 21.4 |

41.28 | 1-5/8 | 9.19 | 0.362 | 66.9 | 22.4 |

44.45 | 1-3/4 | 9.19 | 0.362 | 68.67 | 20 |

50.8 | 2 | 9.19 | 0.362 | 71.71 | 18.1 |

57.15 | 2-1/4 | 9.19 | 0.362 | 74.21 | 16.2 |

63.5 | 2-1/2 | 9.19 | 0.362 | 76.31 | 14.85 |

50.8 | 2 | 11.1 | 0.437 | 67.35 | 25.3 |

50.8 | 2 | 12.7 | 0.5 | 64.00 | 32.3 |

57.15 | 1-1/4 | 12.7 | 0.5 | 66.94 | 29.53 |

63.5 | 1-1/2 | 12.7 | 0.5 | 69.44 | 26.5 |

76.2 | 3 | 12.7 | 0.5 | 73.47 | 22.7 |

88.9 | 3-1/2 | 12.7 | 0.5 | 76.56 | 20.2 |

101.6 | 4 | 12.7 | 0.5 | 79.01 | 17.9 |

Other mesh sizes and style on request | |||||

Stainless Steel (abrasion and corrosion-resistant, high tensile, hard drawn wire)

SS304

Standard alloy = 18% chrome / 8% nickel for excellent corrosion resistance

SS316

Molybdenum is added to the basic 18% / 8% alloy for increased resistance to chemical corrosion.

SS430

Chromium alloy with no nickel for higher resistance to chemicals, atmospheric corrosion and oxidation. Handles temperature up to 1,600 F.

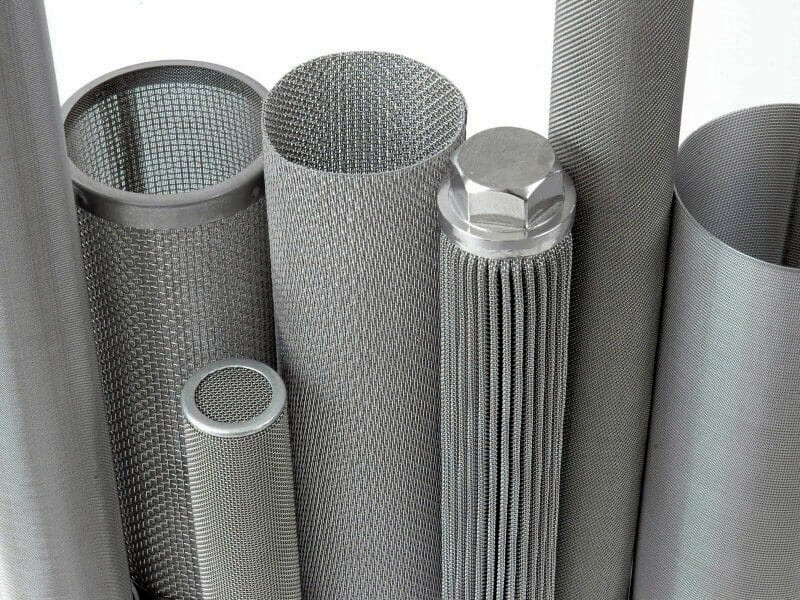

Related Products

We are specialize in filter products more than 10 years with strength of Wedge Wire Screens, Perforated Metal Screen Sheet..