Welcome to Anping County BT Wire Mesh Products Co., Ltd.

News

Products Catalog

News

The structure, advantages, and application areas of stainless steel wedge wire screen

Stainless Steel Wedge Wire Screen is a very important filtration and screening element in many industrial sectors.

Structure of Stainless Steel Wedge Wire Screen

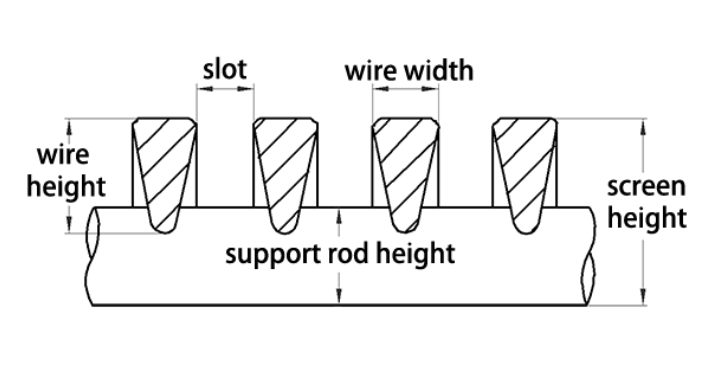

Stainless Steel Wedge Wire Screen, also known as V-Wire Mesh, Slot Screen, or Johnson Screen, is not woven but produced through a special welding and pressing process. Its core structure can be divided into the following parts:

Components:

Supporting Rods: normally thicker stainless steel wires with V-shaped or trapezoidal cross-sections. They form the “skeleton” of the wedge wire screen, determining its strength .

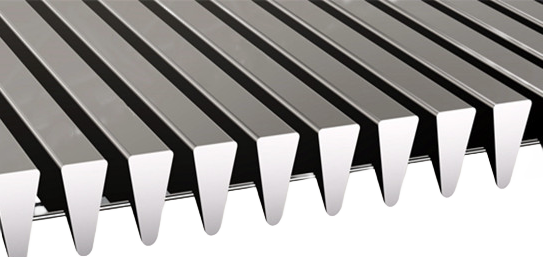

Surface Wires: normally thinner stainless steel wires with V-shaped or trapezoidal cross-sections. They are arranged in parallel, covering the supporting rods.

Manufacturing Process:

Automatic Welding: On precision automated production equipment, surface wires are welded to the support rods at strictly equidistant slot using resistance welding technology. Each intersection is fused together by a powerful current, forming a strong weld.

Core Feature - Wedge-shaped Slots

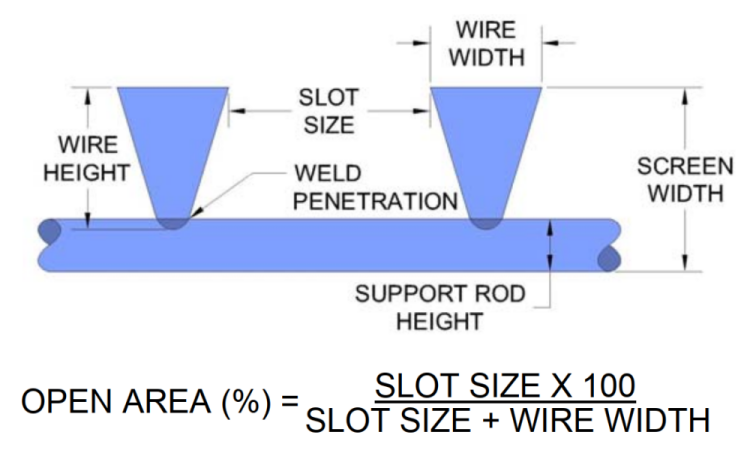

This is the most distinctive and critical structural characteristic of wedge wire screen. As the surface wires are welded onto the sides of V-shaped or trapezoidal support rods, that resulting filtration gaps exhibit a “wedge-shaped” cross-section, a narrower top and a wilder bottom.

Excellent Performance of Stainless Steel Wedge Wire Screen

High Strength and Rigidity

With a strong support frame and all nodes welded together, the wedge wire screen exhibit extremely high mechanical strength and overall rigidity. It can withstand bigger pressure, impact and material loads, is not easily deformed, and has a very longer working life.

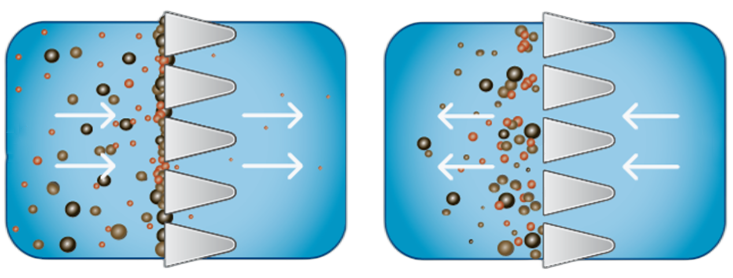

Anti-clogging / self-cleaning Ability

This is one of the most important features of the wedge wire screen. The narrower top and wider bottom wedge-shaped slot design makes it difficult for particles to get stuck in the slits. If the particles close to slit size enter the slit inlet, the increased internal space makes them easily flushed away by the flowing liquid or backwashing force, greatly deducing the risk of clogging.

High Opening Area

Compared to perforated plates or woven mesh of the same aperture, wedge wire screen has a larger effective filtration area. And this translates to higher flow rate and lower pressure loss, significantly improving processing efficiency.

Stable Filtration Accuracy

The gaps are mechanically positioned and welded, ensuring precise and consistent dimensions. Unlike woven mesh, its accuracy does not change due to wire diameter shifts during long-term use, resulting in stable filtration performance.

Wear Resistance & Long Service Life

The wedge wire screen is made of high-quality stainless steel such as SS304 SS316L 2205/2507 Duplex Steel. It has excellent corrosion resistance and wear resistance. The surface wire bear the wear directly. Due to the wedge-shaped gaps, even if the surface wires are partially worn, their effective filtration size can remain unchanged for a considerable time.

Easy to clean and maintain

The smooth surface and non-clogging structure make wedge wire screen very easy to clean. Whether rinsed with water, ultrasonically cleaned, or using backflushing technology, surface residues can be easily removed, resulting in low maintenance costs.

High Machinable

Stainless Steel Wedge Wire Screen can be rolled into cylinder, process into flat screen, conical filter elements, or other various irregular shapes as needed to meet the requirements of different equipment and process.

Application Areas of Stainless Steel Wedge Wire Screen

1. Petrochemical Industry: Screen Tubes, Gas-liquid Separators, Reactor Internals.

2. Mining: Coal Washing Screens, Dewatering Screens, Slurry Filtration, Particle Classification.

3. Water Treatment: Rotary Drum Screen, Disc Filter Screen, Seawater Desalination Screens.

4. Food Industry: Filtration and screening of fruit juices, Beer, Sugar, Starch, and Pharmaceuticals.

5. Paper Industry: Pulp Screening

6. Environmental Protection: Landfill Leachate Treatment, Sludge Detwatering.

Stainless steel wedge wire screen is a rigid screening and filtering material made through a precise welding process, featuring “narrower top and wider bottom” wedge-shaped gaps. It perfectly combines high strength, large flow capacity, long service life and excellent anti-clogging performance. It is an ideal choice in modern industries for handling high flow rates, high impurity content or demanding filtration accuracy conditions.

Next: The Role of Wedge Wire Screens in the Carbon-in-Pulp Method for Gold Mining

Previous: Guardian of Every Spring: How the Wedge Wire Screen Tube Acts as a Precision Filter for Groundwater