High open area, reducing filtration time

Welcome to Anping County BT Wire Mesh Products Co., Ltd.

Welcome to Anping County BT Wire Mesh Products Co., Ltd.

The triangular shaped profiles ensure that the solids do not get lodged in the slots and guarantees the free passage of the filtrate. That makes the Baitong screens perfect for oil extraction. The production process of vegetable oil involves the extraction of oil from plant components, typically seeds. This is mostly done by using a solvent. Wedge wire filter bottoms and screens are ideal to separate the oil from the solids.

Advantages

High open area, reducing filtration time

Self supporting

Custom-made

Perfectly flat screens

The production of starch is a wet process. Whenever solids need to be separated from liquids, Baitong wedge wire screens can be used. We are happy to present our products for the starch industry.

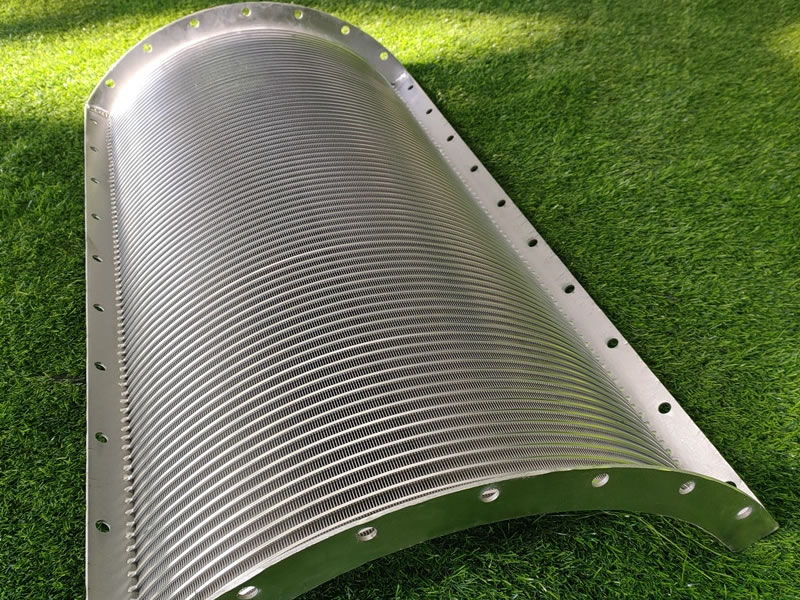

The welded screen consists of V-shaped surface profiles resistance welded onto support profiles.

Advantages

Reversibility=double lifetime. In this specific application the wear is concentrated on the top of the screen. Baitong offers the possibility of reversible screens. If the wear on one side becomes too extensive, you simply turn the screen upside down.

Slot precision. This is one of the most important characteristics of the Baitong screen as it determines the dimensions of the fiber passing through. Baitong guarantees a superb slot precision.

These screens are an alternative to pressure screens for fiber washing, fiber dewatering and germ washing applications. They are also known as ICM or paddle screens. Throughout the years, Baitong has acquired a reputable experience in designing and engineering screens for this specific application.

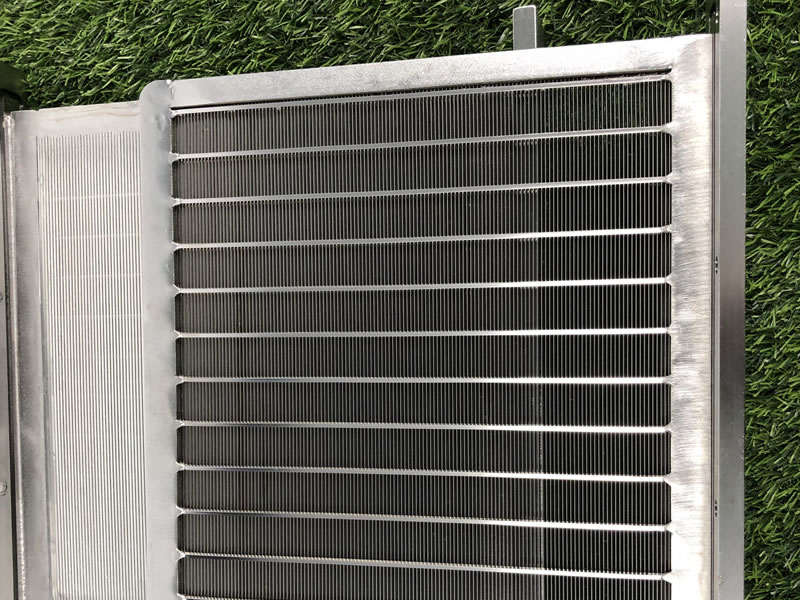

Wedge wire pressure leafs are used in the removal of calcium carbonate from sugar liquor. Pressure leafs require a large filter surface. Baitong is the company capable of producing screens with slots of 30 micron that are large enough for this application.

Technical details

Slot opening: 0.03mm and above

Open area: minimum 3.8%

Dimensions: screen is made to size

Advantages

Strong mechanical construction compared to conventional mesh

Less risk of damage

Larger open area

Shorter filter cycles

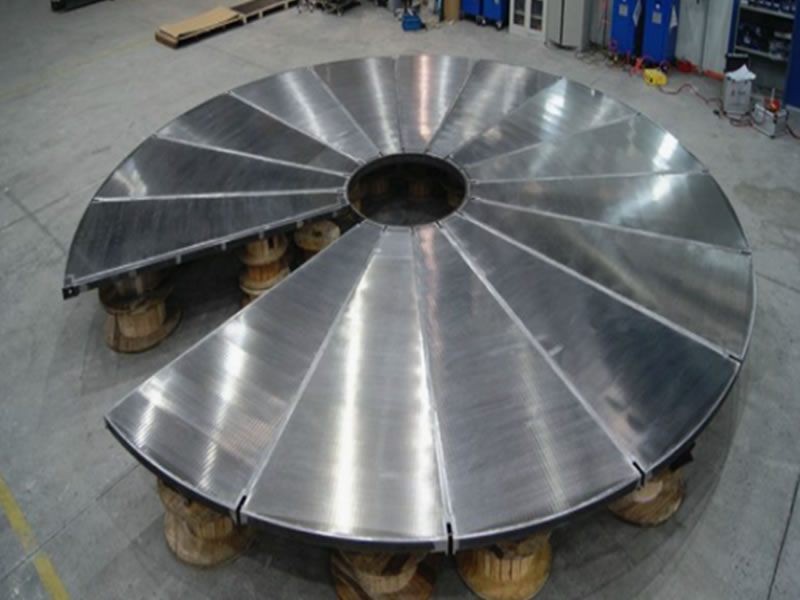

A case study with a false bottom of diam 2100mm showed that the water consumption could be reduced significantly, and the filtration time was reduced by 1.5 hours compared to a false bottom of milled plate.

Technical details

For smaller tuns: rectangular segments, for larger diameters: pie shaped segments

Slot opeings: 0.5-0.75 mm

Open area: 20-30%

Material: mainly 304, in some cases 316L

Advantages

High open area, reducing filtration time

Good cleanability, reducing water consumption

Self supporting

Custom-made

Perfectly flat screens.

We are specialize in filter products more than 10 years with strength of Wedge Wire Screens, Perforated Metal Screen Sheet..