Welcome to Anping County BT Wire Mesh Products Co., Ltd.

News

Products Catalog

News

Performance Advantages and Application Prospects of Stainless Steel Wedge Wire Screen Well Screens

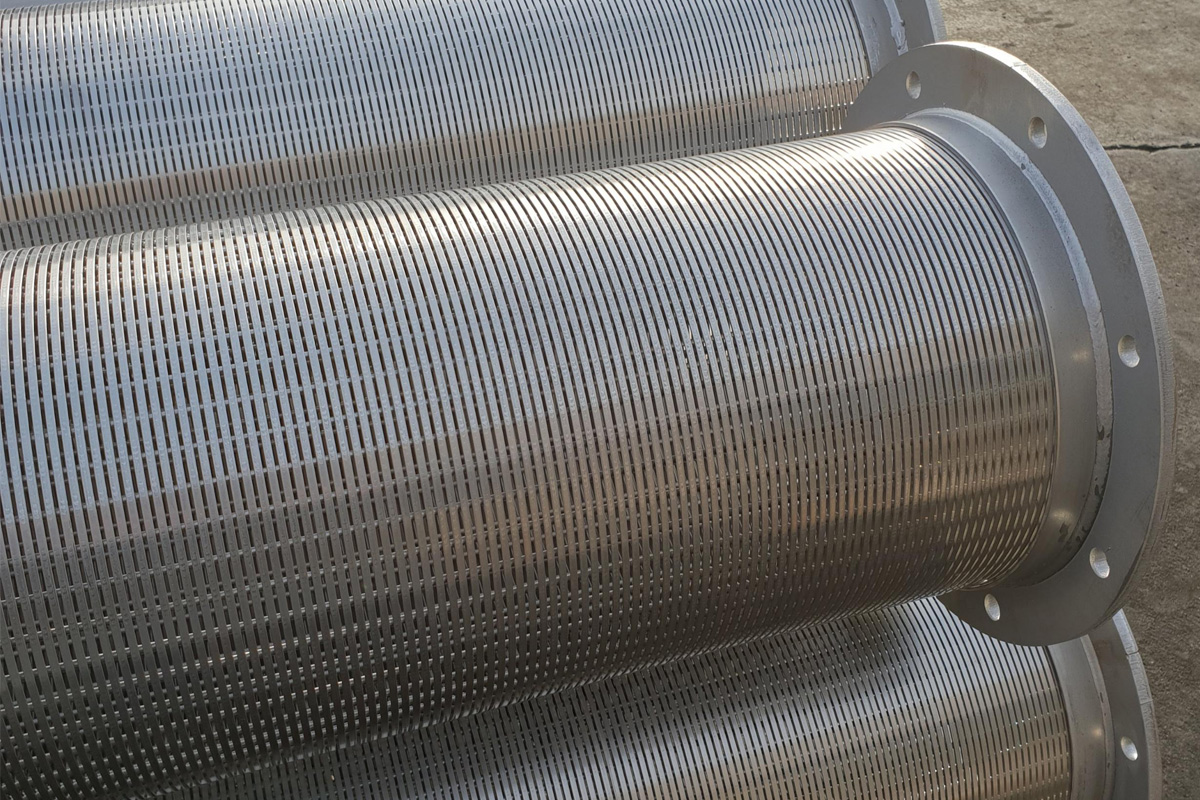

For someone like me, who has spent years deep in the research, development, and production of filtration elements, these precision screens are more than just products; they are a testament to engineering solving real-world problems. Day in and day out, I watch as robust stainless steel wires are transformed through precision welding into the distinct, high-performance form of a stainless steel wedge wire screen well screen. I know from firsthand experience that in modern water extraction, this isn't just a simple component—it's a core solution that dictates efficiency and longevity. From our perspective on the production floor, I want to delve into the inherent advantages and the vast potential of this technology.

The superior performance of a stainless steel wedge wire screen well screen is fundamentally rooted in its unique architecture. It's a world apart from traditional slotted pipes or woven mesh screens. Our process involves using specially profiled wedge wires (V-shaped wires) as the longitudinal support cage, around which identical wires are continuously and uniformly wound. Every crossing point is permanently fused using precision resistance welding. This creates a filtration surface with continuous, uniform, and precisely calibrated gaps. These "screen slots" are the very soul of the stainless steel wedge wire screen. They can be custom-designed to match the grain size of specific aquifer sands, from tens of microns to several millimeters, achieving highly efficient "solid-liquid separation." Unlike woven mesh, which is prone to deformation and clogging, the slots in a stainless steel wedge wire screen are rigid and structural. They maintain their stability under the sustained pressure and surge of groundwater, effectively preventing sand intrusion caused by slot deformation.

Second is its remarkable mechanical strength and corrosion-resistant longevity. We insist on using high-grade 304 or 316L stainless steel as our raw material. This material inherently offers excellent resistance to corrosion from various ions found in groundwater. More importantly, the all-welded construction gives the stainless steel wedge wire screen immense overall strength and structural integrity. It can withstand the enormous pressures from deep aquifers and the inevitable shocks and tensile forces during installation and lowering into the well, unlike some brittle screens that can fracture. In many of our long-term case studies, wells utilizing high-quality stainless steel wedge wire screen casings far outlast those with traditional screens, with some operating reliably for decades without performance decline. From a total-lifecycle cost perspective, while the initial investment might be higher, the extended, maintenance-free service life and consistent output deliver outstanding value.

Third is its superior applicability and environmental benefits. The slots on a stainless steel wedge wire screen are continuous and consistent, ensuring uniform filtration along the entire screen length and preventing localized sand gushing or uneven flow. Whether it's for a civilian agricultural irrigation well, a rural drinking water well, an industrial cooling water well, a recharge well, or even in environmental applications like groundwater monitoring and remediation wells, it provides precise filtration. Furthermore, stainless steel is inherently environmentally benign. It does not leach harmful substances into the aquifer, unlike some synthetic materials or coated products, thereby guaranteeing the purity and safety of the water source.

It is precisely these solid performance advantages that make me profoundly optimistic about the application prospects for the stainless steel wedge wire screen.

As the global call for the sustainable management of water resources grows louder, the efficient and environmentally sound extraction and protection of groundwater has become a universal priority. In this context, market demands for well completion materials are inevitably rising. The old, crude model of "drill a well, use it for a few years, and abandon it" is becoming untenable. The stainless steel wedge wire screen well screen, with its long life, high reliability, and low maintenance, perfectly aligns with the principle of sustainability. It is not merely a tool for water extraction; it is a key infrastructure for protecting aquifer integrity, preventing formation sand loss, and maintaining groundwater stability.

The application fields are poised to become even more diverse. Beyond conventional water extraction, the unique value of the stainless steel wedge wire screen will be unleashed in emerging, demanding fields such as energy wells for ground-source heat pump systems, barrier wells for preventing seawater intrusion along coastlines, and recharge wells for controlling urban land subsidence. For instance, in ground-source heat pump systems, the screen must endure cyclic thermal stresses and demands high heat exchange efficiency—our stainless steel wedge wire screen is often the preferred solution here due to its superior strength and stable flow capacity.

Next: Beyond "Stainless Steel": Five Critical Parameters for Choosing Your Wedge Wire Screen Tube

Previous: Farewell to Sediment, Savor Pure Springs: The Filtration Secrets of Stainless Steel Wedge Wire Scree