Welcome to Anping County BT Wire Mesh Products Co., Ltd.

News

Products Catalog

News

Wedge Wire Screen: The Key to Solving Fine Particle Screening Challenges in Gold Ore CIP/CIL Process

In the CIP (Carbon-in-Pulp) and CIL (Carbon-in-Leach) processes of gold ore extraction, production efficiency and final recovery rate are like two ends of a scale, where precise control at every stage is critical. Among these stages, the screening separation of pulp from activated carbon, especially when dealing with stubborn fine particles, often becomes a bottleneck restricting the entire production line. Traditional screens are prone to clogging, wear out quickly, and suffer from incomplete separation. This not only leads to frequent shutdowns for cleaning but also directly causes losses of activated carbon and gold-bearing fine particles. Every minute of downtime and every gram of gold lost erodes the core profitability of an operation.

It is here that a solution engineered for extreme operating conditions—the Wedge Wire Screen—is emerging as a key to solving this industry challenge through its superior design and performance. It is far more than a simple replacement for standard screens; it is a high-efficiency separation component deeply optimized to address the specific pain points of Carbon-in-Pulp/Leach processes.

The Ingenious Design of Wedge Wire Structure: Tackling clogging at Its Root

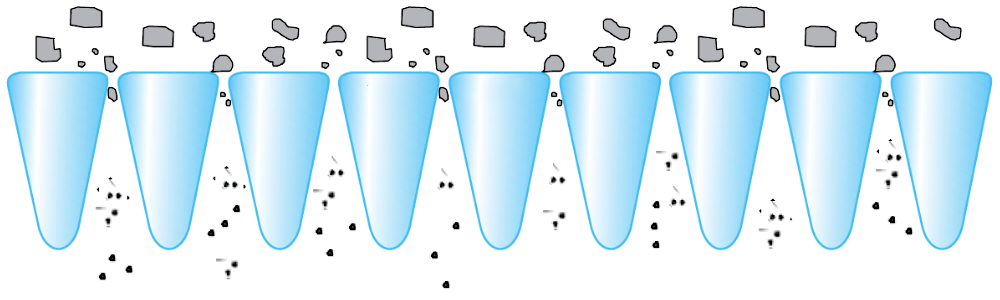

The clogging issue in traditional screens primarily stems from their round or square hole patterns. Fine particles, fibrous impurities, and activated carbon of certain sizes in the pulp easily adhere to and bridge across the hole edges, rapidly forming a dense, blinding layer. The core secret of the Wedge Wire Screen lies in its unique "V"-shaped profile wires. These wires are precisely welded to form continuous, uniformly graded trapezoidal screening slots that narrow from the top to the bottom.

This structure delivers revolutionary advantages: as pulp flows across, particles experience "line contact" with the slot rather than "point contact," significantly reducing attachment points. More importantly, any particle entering the slot is more likely to slide downward and be discharged under gravity or fluid force, unable to become lodged in the gradually narrowing gap. This "self-cleaning" capability ensures the screening surface remains clear, making it an ideal design for handling high-viscosity, fine-particle pulp and fundamentally guaranteeing the continuous, stable operation required by CIL screens and CIP screens.

Multidimensional Performance Advantages: Delivering Value Beyond Screening

For gold ore screens, anti-clogging is just a basic requirement. In the harsh, abrasive pulp environment, a screen must also possess long service life, high precision, and sufficient mechanical strength. Stainless Steel Wedge Wire Screens excel across all these dimensions.

Exceptional Wear Resistance and Anti-Deformation Capability: High-quality wedge wires are typically made from high-strength stainless steel or specially hardened steel. Their "V"-shaped profile acts like a miniature structural beam, providing far greater resistance to bending and impact than round wires. This means that under continuous pulp flushing and activated carbon impact, the slot size remains stable over the long term, preventing issues like coarse particle leakage or poor separation due to screen deformation. This ensures precise control over the activated carbon's size distribution, which is crucial for the adsorption efficiency of Carbon-in-Pulp/Leach processes.

Precise Separation and High Throughput: The screen slots of a wedge wire screen are guaranteed by precise tooling and welding processes, resulting in extremely uniform slot widths. This enables more accurate size separation, effectively intercepting oversized activated carbon particles while allowing the gold-bearing solution to pass through quickly. Its smooth surface and open structure offer low flow resistance and high processing capacity per unit area, meeting the needs of modern gold ore processing plants for large-scale, high-efficiency equipment.

Superior Strength and Stability: The integrally welded structure of the Wedge Wire Screen is robust, capable of withstanding significant tension and load, making it suitable for large vibrating screens or static sieve bends. It is less prone to fatigue cracking under strong vibration, significantly enhancing reliability.

A Solution Tailored for Carbon-in-Pulp/Leach Processes

Within the CIP/CIL circuit, different stages have specific requirements for screens. Whether it's pre-leach trash removal, inter-stage screening to ensure smooth counter-current flow of activated carbon, or the final loaded carbon recovery stage, Wedge Wire Screens can provide targeted solutions. Manufacturers can offer deep customization based on specific process parameters—such as pulp density, particle size distribution, activated carbon particle size (typically 6-16 mesh), throughput, and equipment type (e.g., peripheral discharge screens, vibrating screens). This includes selecting the most suitable wire material (e.g., 304, 316L stainless steel, or even higher-grade wear-resistant alloys), determining the optimal slot width (ranging from 0.1mm to several millimeters), and designing the most stable screen surface support structure.

This customization ensures that every screen put into service is a "dedicated tool" perfectly matched to its specific operating conditions, thereby maximizing the screen's overall performance.

Investing in Efficiency and Returns: The Long-Term Value of Wedge Wire Screens

The value of choosing a high-performance Wedge Wire Screen should not be measured solely by the spare part procurement cost. It should be viewed as a strategic investment in enhancing overall operational efficiency. Its long service life reduces replacement frequency and spare parts inventory pressure. Its exceptional anti-clogging significantly cuts downtime for cleaning and associated labor costs. The precise and efficient separation directly safeguards activated carbon and gold-bearing particles, providing a solid foundation for improving the final gold recovery rate. For any gold ore operation striving for operational excellence, employing reliable and efficient Wedge Wire Screens in the critical screening stage is a wise decision for optimizing Carbon-in-Pulp/Leach processes, reducing costs, increasing efficiency, and strengthening core competitiveness.

In summary, faced with the severe challenge of fine particle screening in gold ore Carbon-in-Pulp/Leach processes, the Wedge Wire Screen, with its comprehensive performance in anti-blinding, wear resistance, efficiency, and stability, has evolved from a quality spare part option into a key process component that ensures the continuous, efficient, and economical operation of modern mineral processing plants. It is not merely a tool for screening materials but a crucial lever for optimizing production process and enhancing economic returns.

Next: Farewell to Sediment, Savor Pure Springs: The Filtration Secrets of Stainless Steel Wedge Wire Scree

Previous: The 5 Key Technical Advantages of High-Performance Wedge Wire Screens Designed for CIL/CIP Processes