Welcome to Anping County BT Wire Mesh Products Co., Ltd.

News

Products Catalog

News

The 5 Key Technical Advantages of High-Performance Wedge Wire Screens Designed for CIL/CIP Processes

In the heart of gold ore processing—the Carbon-in-Leach (CIL) and Carbon-in-Pulp (CIP) circuits—the efficient separation of activated carbon from slurry is a decisive factor for both recovery rates and operational costs. Traditional separation equipment often falls short, becoming the "weak link" in the production chain due to persistent issues like blinding, rapid wear, and insufficient separation accuracy. Today, a profoundly optimized high-performance wedge wire screen is transforming this landscape through its engineered technical features. It represents far more than a simple component upgrade; it is a systems-based solution meticulously tailored for the demanding conditions of CIL screens and CIP screens. This analysis delves into its five core technical advantages, revealing why it has become the premier choice for modern gold ore screen applications.

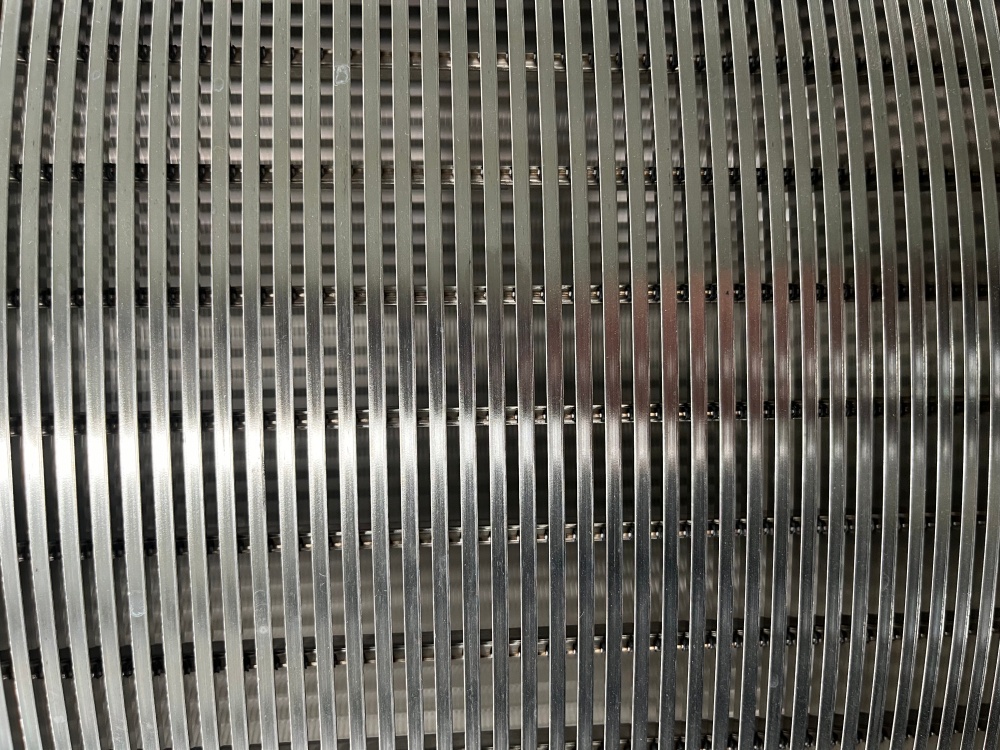

Advantage 1: Revolutionary Anti-Clogging Structure for Uninterrupted Operation

Clogging is the primary challenge for any CIP screen handling fine, viscous slurries. Traditional screen apertures are prone to particle trapping, creating "dead zones" that drastically reduce active screening area and necessitate frequent, costly downtime for cleaning.

The solution lies in the unique "V"-shaped profile wire and continuous slot design of the high-performance wedge wire screen. Its trapezoidal slots, wider at the top and narrower at the bottom, facilitate a linear sliding contact for particles rather than a point-contact jamming. This engineering yields two critical effects: a "self-cleaning" action, where particles are more likely to slide out of the narrowing gap under gravity and slurry flow, and a "no blind-spot" performance, as the continuous slots eliminate the inherent material-trapping zones of perforated plates. For gold ore screens in abrasive circuits, this translates to near-maintenance-free continuous operation, maximizing equipment availability and truly embodying the concept of an anti-blinding screen.

Advantage 2: Exceptional Wear Resistance & Dimensional Stability for Longevity & Precision

Under the constant abrasive assault of high-velocity slurry and impacting activated carbon, screen wear leads directly to slot enlargement and loss of separation accuracy, resulting in abnormal carbon loss or slurry "short-circuiting."

Engineered for extreme duty, the wedge wire screen offers dual reinforcement through material and structure. Firstly, it is fabricated from ultra-high-strength stainless steel or specialized wear-resistant alloys with superior surface hardness. Secondly, the "V" profile itself acts as a miniature structural beam, granting each wire remarkable resistance to bending and deformation. This combination ensures exceptional long-term stability of the slot dimensions, guaranteeing that its core function as a carbon recovery screen—precisely controlling the activated carbon particle size range—remains consistent over time. Investing in this long-life screen means lower spare part replacement frequency and stable process control, leading to a significantly lower total cost of ownership.

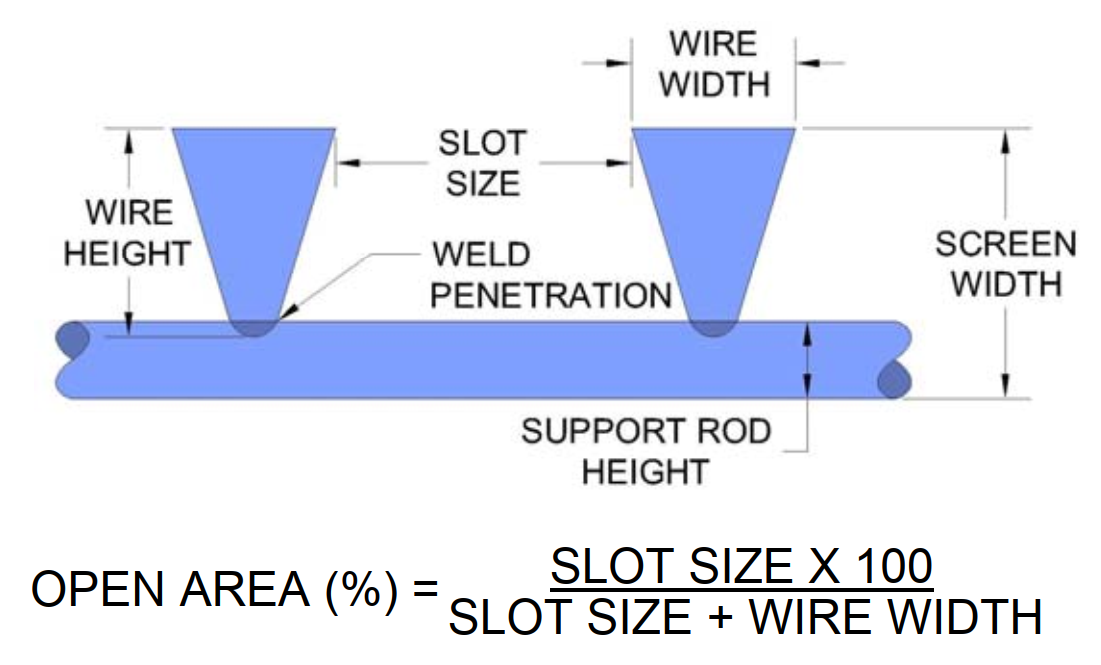

Advantage 3: High Open Area & Optimized Flow Dynamics for Enhanced Throughput

The effective open area of a screen directly dictates its processing capacity. Traditional screen plates often suffer from limited open area due to the need to maintain structural integrity.

The linear support structure of the wedge wire screen allows for an effective open area exceeding 35% while maintaining overall mechanical strength, far surpassing that of typical perforated plates. Furthermore, its smooth wire surface and unobstructed flow path minimize slurry flow resistance. This characteristic is vital for gold ore screens in large-scale CIL/CIP plants, enabling higher throughput within the same equipment footprint or allowing for more compact equipment for a given duty, thereby optimizing both capital and operational expenditures.

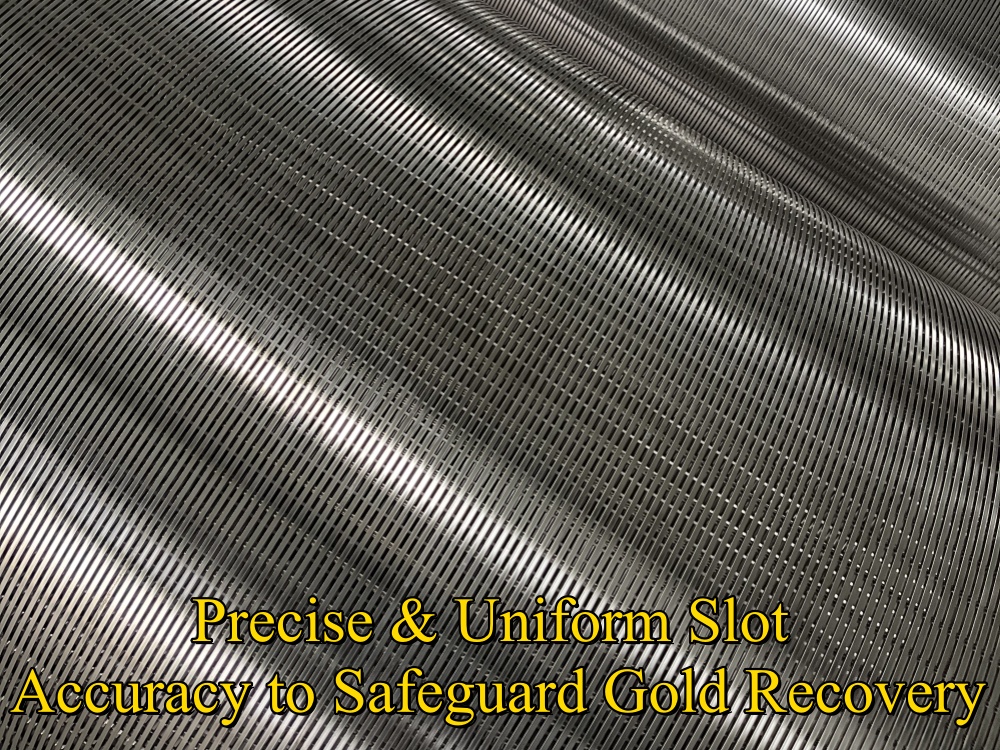

Advantage 4: Precise & Uniform Slot Accuracy to Safeguard Gold Recovery

Separation accuracy is the defining attribute of any carbon recovery screen. Inconsistent slot geometry causes areas of "short-circuiting" (carbon loss) and areas prone to blinding, severely compromising adsorption efficiency and metal recovery.

In high-performance wedge wire screens, slot width is guaranteed by precision tooling and automated welding processes. The tolerance for each continuous slot can be controlled within a minimal range (e.g., ±0.05mm), ensuring consistent separation performance across the entire screening surface. This precise control reliably retains activated carbon within the adsorption circuit while allowing barren or pregnant solution to pass through efficiently. It acts as a fundamental safeguard against the inadvertent loss of carbon or gold-bearing fines due to screening inconsistencies, directly protecting the final recovery rate.

Advantage 5: Superior Mechanical Strength & Structural Rigidity for High-Intensity Screening

On line shake screening equipment like vibrating screens, panels must endure continuous cyclic stress and high-frequency vibration. Insufficient structural rigidity can lead to fatigue failure and accelerated wear on support beams.

The robust, integrally welded construction and inherent bending resistance of the profile wire give the high-performance wedge wire screen exceptional overall rigidity and fatigue resistance. It can withstand higher tension loads, ensuring a tight, rattle-free fit within the screen frame. In the rigorous environment of CIP/CIL processing, this robustness translates to lower failure rates, fewer unplanned stoppages, and reliable compatibility with large, modern screening machinery.

Conclusion: The Transition from Component to Process Core

In summary, the high-performance wedge wire screen, engineered specifically for CIL/CIP processes, achieves a value leap from a common wear part to a critical process guarantor through its five key advantages: anti-blinding design, superior wear resistance, high throughput, pinpoint accuracy, and exceptional strength. It directly addresses the core challenges in gold ore screen applications: continuity, cost-efficiency, and recovery.

Selecting this deeply optimized wedge wire screen is, in essence, choosing a more stable, efficient, and profitable production model. It is not merely replacing a part but fundamentally innovating the screening stage within the carbon-in-pulp process. For gold mining operations committed to enhancing core competitiveness and achieving sustainable development, understanding and leveraging these technical advantages is a decisive step toward securing a leading position in a competitive market.

Next: Wedge Wire Screen: The Key to Solving Fine Particle Screening Challenges in Gold Ore CIP/CIL Process

Previous: The Guide to Selecting Screens for Gold Mine CIP/CIL Plants: From Specifications to Materials