Welcome to Anping County BT Wire Mesh Products Co., Ltd.

News

Products Catalog

News

The Guide to Selecting Screens for Gold Mine CIP/CIL Plants: From Specifications to Materials

In the Carbon-in-Pulp (CIP) and Carbon-in-Leach (CIL) processes for gold extraction, the efficient separation of activated carbon from slurry is the critical lifeline for ensuring recovery rates and economic returns. The core component of this lifeline—the screen—and the correctness of its selection directly determine a plant's ability to operate continuously, stably, and efficiently. Faced with a dazzling array of gold ore screen products on the market, how does one make an accurate and informed choice? This guide will systematically break down the selection logic for CIL screens and CIP screens, step by step, from core parameters to key materials.

Step 1: Define Process Requirements – The Fundamental Starting Point for Screen Selection

Selecting a screen is far from a simple matter of matching dimensions; it must begin with a deep understanding of your own process. The following questions must first be clarified:

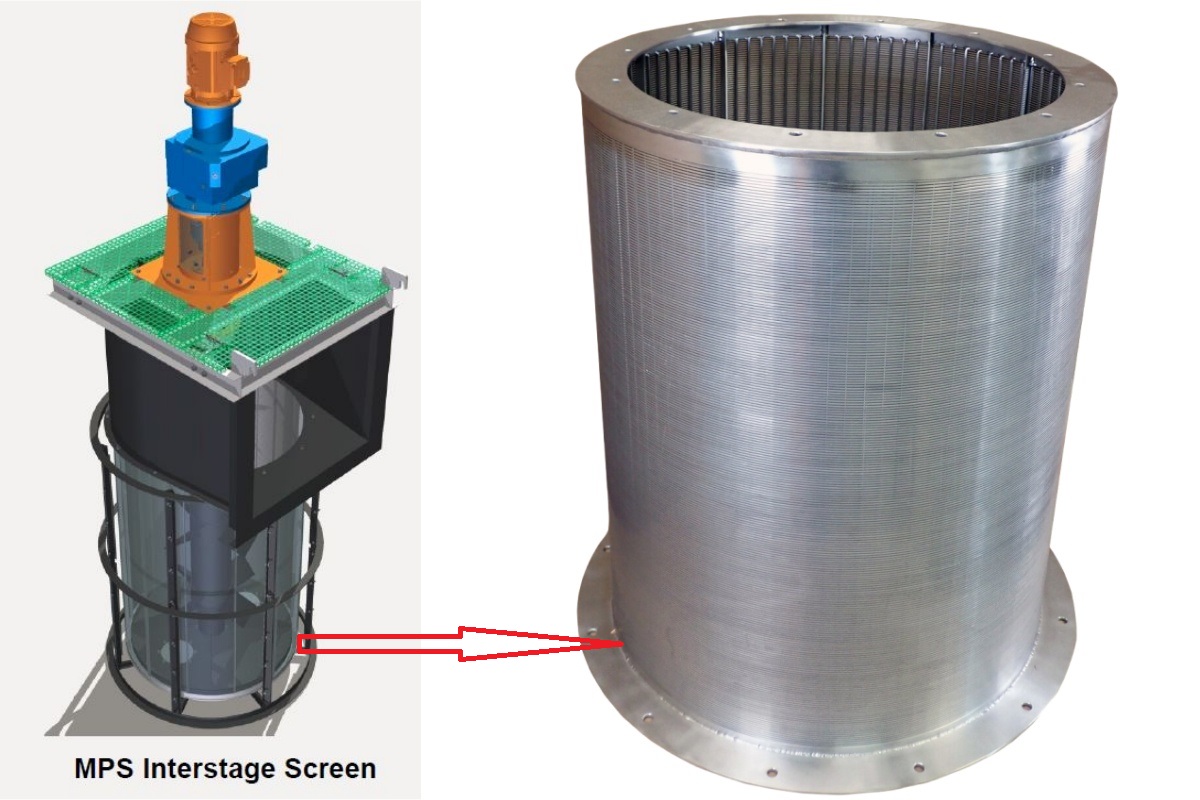

1. Process Stage Positioning: Is your screen for inter-stage screening, safety screening, or final loaded carbon recovery? Different stages have vastly different requirements for separation accuracy and blinding resistance.

2. Feed Characteristics: What are the slurry's particle size distribution, viscosity, clay content, pH, and abrasive mineral content? This directly determines the intensity of "attack" the screen must withstand.

3. Activated Carbon Specifications: The particle size range (typically 6-16 mesh), density, and strength of the activated carbon used are key input parameters.

4. Operating Conditions: The type of screening machine (e.g., vibrating screen, peripheral discharge screen), throughput (m³/h), and runtime (e.g., 24/7 continuous operation) form the design basis.

Only by clarifying these points can your selection process move from "educated guessing" to "data-driven decision making."

Step 2: Analyze Core Performance Parameters – Understanding the Technical Data Sheet

When reviewing a screen technical specification sheet, focus on the following parameters. Together, they define the screen's performance limits:

| Parameter Category | Specific Parameter | Impact on Process & Interpretation |

| Separation Accuracy | Slot Width / Aperture | This is the soul of a carbon recovery screen. The size must precisely match the activated carbon particle size to ensure 100% carbon retention and free slurry passage. Tolerance is typically required to be within ±0.05 mm. |

| Structural Strength | Wire Diameter / Plate Thickness | Determines the screen's resistance to deformation and overall service life. Sufficient wire diameter is fundamental to maintaining slot integrity and preventing "short-circuiting" under strong vibration and high load. |

| Throughput Capacity | Effective Open Area | A higher open area allows greater flow capacity for a given screen area. Wedge Wire Screens with high open area can help reduce equipment size or increase processing capacity. |

| Flow Characteristics | Screen Surface Design & Slope | Affects slurry flow distribution and discharge speed. An optimized design can reduce material build-up and promote stratification. |

For CIP screens and CIL screens, "separation accuracy" and "structural strength" are a core pair of contradictory requirements that must be balanced based on the specific operating conditions.

Step 3: Select Key Materials – The Foundation Determining Service Life

The material is the screen's first line of defense against wear and corrosion, directly linked to replacement cycles and total cost of ownership. Common material choices include:

304 Stainless Steel: Offers good overall corrosion resistance, suitable for most neutral or weakly corrosive slurries, and represents a cost-effective choice.

316L Stainless Steel: The addition of molybdenum significantly enhances resistance to chlorides and acidic environments. For processing complex, highly corrosive gold ore slurries, 316L Wedge Wire Screens are often a more reliable investment. Their longer lifespan can amortize the higher initial cost.

Special Abrasion-Resistant Steel / Polyurethane Cladding: In extremely abrasive conditions, higher hardness wear-resistant steel or polyurethane-clad wires can be used in critical areas to specifically extend service life.

Core Recommendation: Do not select materials based solely on initial price. Conduct a full lifecycle cost analysis, calculating the screen cost per ton of ore processed. High-quality materials often prove more economical in the long run.

Step 4: Evaluate Structural Design – The Guarantee of Efficiency and Anti-Clogging

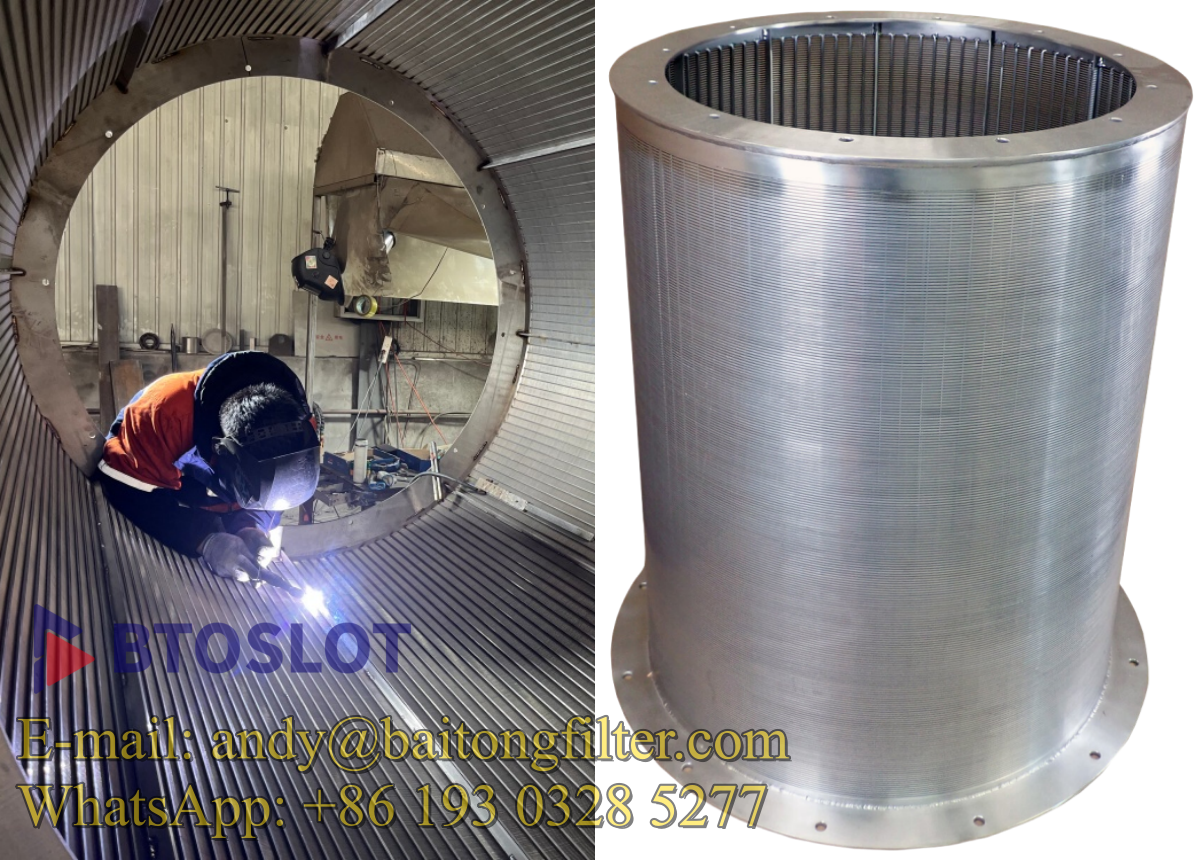

Superior structural design can fundamentally enhance performance. Currently, the Wedge Wire Screen is becoming the mainstream choice for CIP/CIL processes due to its unique design:

Anti-Clogging Design: The "top-wider, bottom-narrower" channel formed by its V-shaped wires and continuous slots effectively guides particles through, preventing lodging, and is key to achieving continuous operation.

High Precision & Stability: Precision welding ensures uniform slot dimensions. The V-shaped profile provides greater bending resistance, ensuring slots do not deform during long-term use.

Modularity & Compatibility: Is the design easy for quick replacement? Can it perfectly fit your existing screening machine or adsorption tank? This relates directly to maintenance convenience and downtime.

Step 5: Make a Comprehensive Decision and Evaluate Suppliers

After completing the above technical analysis, the final decision should be based on:

1. Technical Compatibility: Does the supplier have a deep understanding of CIP/CIL processes? Does their solution target your specific pain points (e.g., fine clay blinding, carbon particle abrasion)?

2. Quality Traceability: Can they provide material certificates, weld inspection reports, and other quality documentation?

3. Proven Track Record: Do they have verified successful applications in gold ore projects of similar scale and feed characteristics?

4. Service & Support: Can they provide full-cycle support from selection and installation guidance to after-sales maintenance?

In summary, selecting a screen for your gold ore CIP/CIL plant is a systems engineering task. It requires you to start from the process, look beyond the surface of parameters, materials, and design, and gain insight into their true impact on long-term operational efficiency and cost. Choosing the right gold ore screen is not merely replacing a component on a machine; it is laying a solid foundation for the stability and efficiency of the entire adsorption and recovery process. We hope this guide assists you in making a confident and informed decision.

Next: The 5 Key Technical Advantages of High-Performance Wedge Wire Screens Designed for CIL/CIP Processes

Previous: The Core Role of Johnson Screens in Gold Mine Carbon-in-Leach and Carbon-in-Pulp Processes